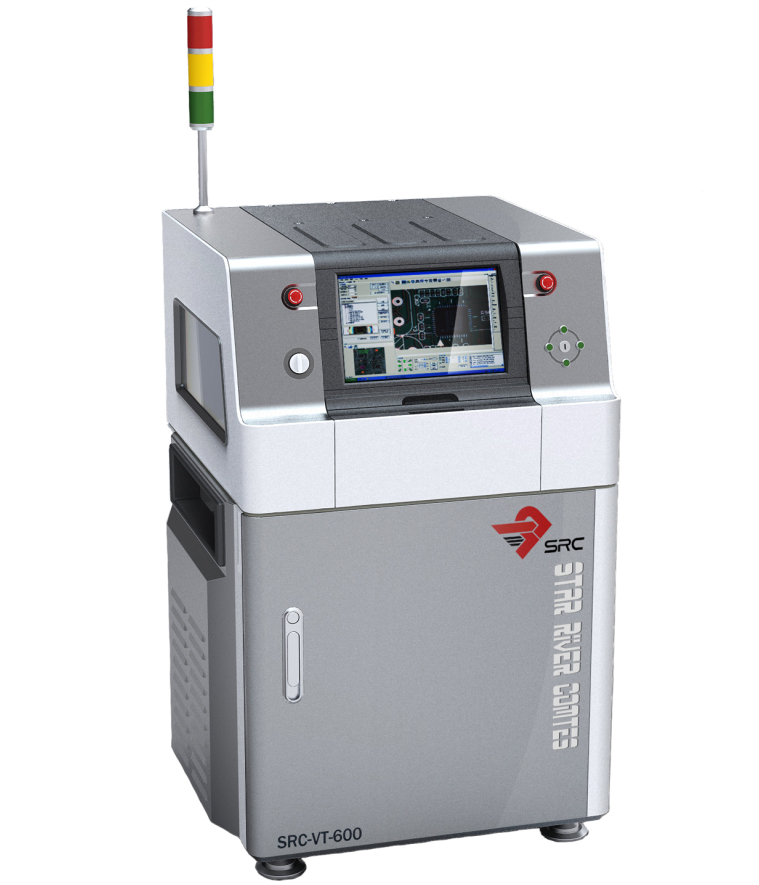

Inline automatic optical tester

Technical data

|

model |

VT-A600 |

|

|

Detection Indicator |

delivery method |

Servo motor + guide rail + ball screw |

|

Check item |

Device missing, dislocation, wrong part, side stand, reverse part, broken, wrong polarity, lack of solder, multi-solder, continuous welding, raised leg, OCR , DIP through hole error, barcode, etc. |

|

|

Type of light source |

Multi-angle four-color ring tower LED light source (red, green, blue, white) |

|

|

Recognizable barcode |

Code39 , Code128 , Interleaved 25 , EAN13, PDF-417, Data Matrix |

|

|

camera |

Industrial-grade high-speed CCD color camera |

|

|

PCB size range |

40*40-500*600mm |

|

|

Substrate thickness range |

0.5-5mm |

|

|

Maximum device height |

+40mm , -60mm |

|

|

Minimum device |

0201 (customized to measure 01005 ) |

|

|

Device off-angle |

0~360 degrees |

|

|

Image resolution |

15 μm/ pixel (custom up to 8 μm/pixel) |

|

|

Dimensions (mm ) (L*W*H ) |

1000 × 1000 × 1500 (excluding alarm light) |

|

Product technical features

1. Mounter data import function

The data of the placement machine can be used to automatically generate programming data, which can greatly improve the programming speed.

2. Asynchronous manual discrimination operation

The operator's judgment is carried out synchronously with the machine test , and the test situation of the first 20 boards can be seen, which can be used in conjunction with the automatic front and back function to greatly improve the detection speed.

3. Select MA RK point arbitrarily

In addition to the traditional circular, rectangular, cross, and triangular marks as MARK points, any characteristic marks can also be used as MARK points. Up to 3 spare MARKers can be selected to ensure board positionability

4. Powerful detection capability of lithography resistors

Powerful automatic adjustment function, even for very dark lithography resistors, you can deal with it freely without adjusting the light.

5. Discrete component color ring test

The industry-reliable color wheel component testing technology can automatically remove the influence of light and extract the color wheel color information for testing.

6. Any angle measurement method

All component, foot, solder and bridge tests can be tested at any angle.

7. Automatic segmentation of IC pins and discrete component solder pins

Automatically divide IC pins and discrete component solder pins and automatically set test parameters for each pin. It avoids the trouble of programming the solder volume and short-circuit window one by one, and the programming speed is more than 5 times faster than that of the peers.

8. Powerful barcode recognition function

It can automatically identify 1D and 2D barcodes, and the barcode size is not limited by the size of the field of view.

9. Perfect SPC statistical function

Complete industrial process control can export statistical data to provide data support for continuous improvement of production line quality.

10. Unique intelligent weight analysis method

Unique patented algorithm (patent number ZL 2009 1 0236019.5), powerful fault tolerance, only need to train a few boards to test stably, extremely low false positive rate and missed judgment rate, no complicated parameter modification, make each operation Workers can easily deal with it.

11. The card board structure with patented technology can easily deal with the edgeless circuit board (patent number ZL 2009 2 0105338.8)

The automatic clamping card structure is convenient for picking and placing the circuit board; the distance between the circuit board components and the edge of the board can be easily handled without additional fixtures or pallets.

12. Automatic front and back function

The automatic front and back function makes double-sided testing easy and simple.

13. Unique dimension measurement function

Break through the original AOI test project and let AOI play a greater role. Accurately measure the aperture size, groove size, irregular shape area, etc. on the PCB board.